September 13th, 2012 : : Nick : :

Please join us for a casual salon-style discussion about the concept of ‘public space’ and what it means in Omaha. We will have drinks and snacks to help encourage conversation.

Wednesday, September 26, 2012

7pm

FREE

Emerging Terrain Studio

1717 Vinton

Download the event poster to hang up on your wall!

July 28th, 2012 : : Nick : :

Change happens in fits and starts.

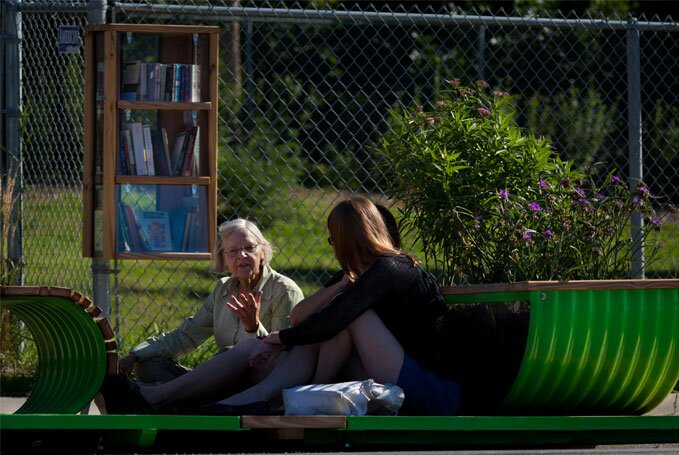

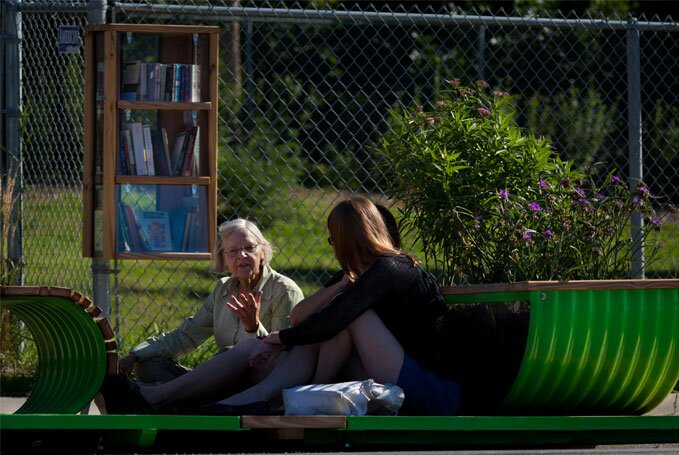

At its most basic, the Trug: Leavenworth project—a partnership between the Greater Omaha Chamber and Emerging Terrain—provides some public space and brightens up the steet in an area that is considered by some to be a little rough around the edges.

But since the Trugs are only out on the street for four months, we hope there can be some lasting effects after the Trugs are removed this autumn. We want the project to be a catalyst—a spark—that sets off a cascade of activity. We are now halfway through the summer, and we are seeing some very promising things that are starting to look like that cascade just might be beginning in various ways.

Leavenworth Restriping

This weekend marks the beginning of the City’s restriping of Leavenworth Street between 13th and 31st Streets—which includes the Trug segment!

Although many factors played into the City’s decision to remove a lane of car traffic and add a bike lane, the Trug: Leavenworth project helped to encourage and accelerate the process. We worked closely with the City for the past year as the Trugs were developed, and early on we included schematic proposals for how the street could be transformed through restriping. We held joint community meetings about both initiatives, championing each other’s projects. Like the Trugs, the City sees restriping as a lightweight way to have a big impact on the neighborhood. We think the restriping is a big success for everyone—the City, the Trug project, and of course the neighborhood. We are happy to have played a part in this permanent change to the street.

Photo by Bryce Bridges Photographic

Books!

The Little Free Library has garnered much excitement and use. The Omaha Public Library and Midtown Neighborhood Alliance partnered to initiate the installation of a weather-resistant bookcase from which neighborhood residents can borrow or swap books. OPL has kept the little library stocked with donated books, which then make their way into individuals’ and families’ possession. Similar to the Trugs, the idea for the little library is borrowed from projects happening in other areas. This one was designed to complement the Trugs and built using leftover Trug materials, but people have expressed interest in seeing more little free libraries around town. Perhaps groups all over town will install and stock little free libraries in their neighborhoods?

Photo by Jaim Hackbart, Inkline Press

Neighborhood Visions

Neighborhood resident, business owner, and artist Jaim Hackbart’s Vision Tree project provided a beautiful and interactive way for individuals to express their hopes and ideas for community improvement. She spent part of each day for a week actively seeking out and engaging other local residents and passersby. Each person wrote their vision on a swatch of paper (made from donated pieces of original art) and tied it to one of the Trug trees. On the final day of the project, Jaim and other area artists each took a 2-hour shift to hand out flowers in the neighborhood and wish each recipient a “nice day.” As Jaim says, “Transformation begins with a thought…transformation happens with an action.” She has expressed how the project has personally changed the way she sees and interacts with her community and the other people in it.

We have been so moved by the project—its thoughfulness, the impressive number of people involved, and its humanity—that we are currently looking through all the vision notes for something that might spark another creative public space project in the neighborhood that can follow when the Trugs move on.

All of this has happened in just the first two months of the project; we can’t wait to see what happens in the next two months and beyond…

April 26th, 2012 : : Nick : :

With the official Trug: Leavenworth kickoff scheduled for May 24th (mark it on your calendars!), I am in the middle of making sure the Trug platforms and seating/planter modules are constructed in time for the launch. Yesterday afternoon I dropped off the final set of corrugated metal to be painted at Helm Auto Body. Since I’m currently waking-eating-sleeping Trug design and fabrication, I’m going to use this opportunity to tell you about the design process of the corrugated metal seating/planter modules.

Last summer, soon after the Greater Omaha Chamber suggested that we collaborate on a project to enliven a section of Leavenworth Street (more on that another time), Anne and I looked at ubiquitous industrial materials that would allow us to design and deploy something in a short amount of time.

We became interested in corrugated metal pipe (aka culvert pipe) as a versatile, common, and durable material that comes in a wide range of sizes. Early ideas used pipe sections as planters that did not require much material manipulation, relying on sheer number for impact. We drew inspiration from the Walklet, Parking Day, Parallel Park, and other temporary urban installations. The design evolved as we proposed cutting and reconfiguring pieces of the pipe to make not only planters, but seating as well.

The real breakthrough came when we finally visited Contech in Wahoo and learned that annular pipe (there is also a helical variety) is still made in the way it’s been done for a century: by individually hand-feeding sheets of corrugated metal into a roller.

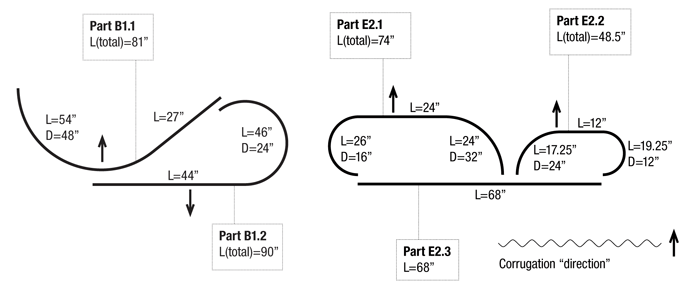

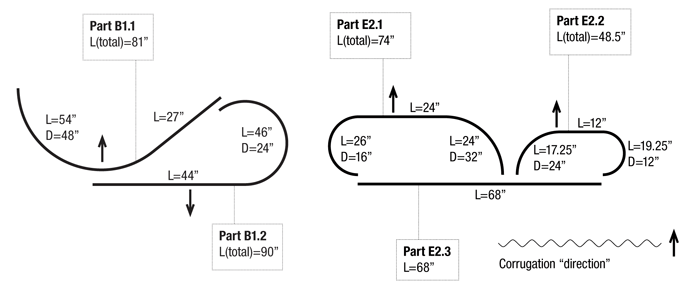

We saw the possibility for partially rolled sheets, and the guys at Contech were happy to try it out. After many more design iterations (with plenty of ugly ones along the way), we arrived at the looping, peeling, ribbonlike forms of the Trug seater/planter modules—shapes that come from the material and fabrication method.

Because the shapes are so closely linked with the tooling, the fabrication drawings can be very simple. And since each piece is rolled by hand on demand, it allows for the design to be approached “parametrically”—i.e., as a system based on rules and variable parameters. In this case, we have a system made up of straight and curved sections of corrugated metal, but the lengths and diameters can change to make various types of seating and planter modules.