Trug Life, Part 1

With the official Trug: Leavenworth kickoff scheduled for May 24th (mark it on your calendars!), I am in the middle of making sure the Trug platforms and seating/planter modules are constructed in time for the launch. Yesterday afternoon I dropped off the final set of corrugated metal to be painted at Helm Auto Body. Since I’m currently waking-eating-sleeping Trug design and fabrication, I’m going to use this opportunity to tell you about the design process of the corrugated metal seating/planter modules.

Last summer, soon after the Greater Omaha Chamber suggested that we collaborate on a project to enliven a section of Leavenworth Street (more on that another time), Anne and I looked at ubiquitous industrial materials that would allow us to design and deploy something in a short amount of time.

We became interested in corrugated metal pipe (aka culvert pipe) as a versatile, common, and durable material that comes in a wide range of sizes. Early ideas used pipe sections as planters that did not require much material manipulation, relying on sheer number for impact. We drew inspiration from the Walklet, Parking Day, Parallel Park, and other temporary urban installations. The design evolved as we proposed cutting and reconfiguring pieces of the pipe to make not only planters, but seating as well.

The real breakthrough came when we finally visited Contech in Wahoo and learned that annular pipe (there is also a helical variety) is still made in the way it’s been done for a century: by individually hand-feeding sheets of corrugated metal into a roller.

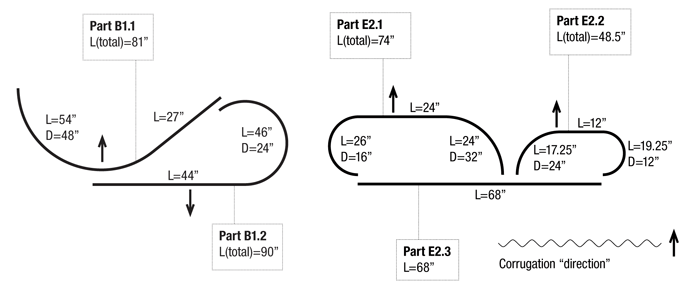

We saw the possibility for partially rolled sheets, and the guys at Contech were happy to try it out. After many more design iterations (with plenty of ugly ones along the way), we arrived at the looping, peeling, ribbonlike forms of the Trug seater/planter modules—shapes that come from the material and fabrication method.

Because the shapes are so closely linked with the tooling, the fabrication drawings can be very simple. And since each piece is rolled by hand on demand, it allows for the design to be approached “parametrically”—i.e., as a system based on rules and variable parameters. In this case, we have a system made up of straight and curved sections of corrugated metal, but the lengths and diameters can change to make various types of seating and planter modules.